American-Made Bedding

We strive to go beyond creating quality home goods. We want to make this country a better place - any way we can.

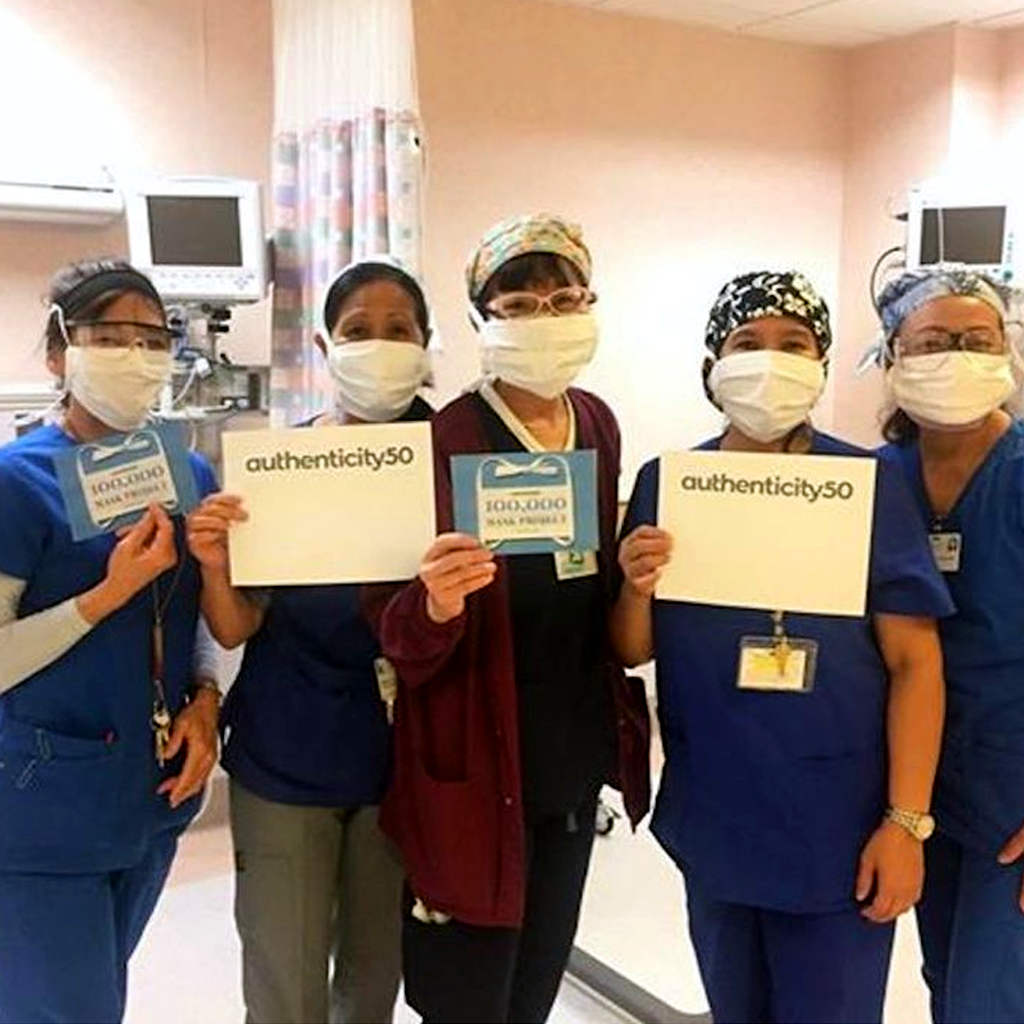

Since our founding in 2016, we've created and run giveback campaigns and fundraisers to support communities in need across the country. With the help of the amazing A50 community, we've donated products and thousands of dollars to many incredible organizations.

We're so proud to make a positive impact on our community. Keep reading to learn more about our impact!

American-Grown Cotton

Learn MoreAmerican-Grown Wool

Learn MoreWoven in Washington

Learn MoreSpun & Knit in North Carolina

Learn MoreWoven in South Carolina

Learn MoreWoven in Maine

Learn MoreSewn in New Jersey

Learn MoreMade in California

Learn More