The State of A50 2021

In spite of the continued global Covid-19 pandemic, we’re striving to deliver more value, be good stewards of the environment, offer better customer service and build a better Authenticity50 for you.

The reason many of you find Authenticity50, buy our products, and become loyal customers, is because we’ve never wavered from our North Star - that is to make the best products in the world here in America, and to build a company that does the right thing. Our entire team was challenged on all fronts in 2020, and these obstacles have strengthened us and reminded us why we do what we do.

For those customers and fans who are new to us - this is our State of A50 - an overview of what happened in 2020, and a look at 2021 and the upcoming holiday season. It gets into the nitty gritty - giving you a level of transparency and understanding of our business that you just won’t find from other companies. We believe it is important and helpful for you all to understand what’s been going on ‘behind the seams’ each year, and many of you have expressed appreciation that we do so. We’d like to thank you all so much for your continued support of A50, and for taking the time to read this.

Supply Chain, Supply Chain, Supply Chain

From 1919 to 2019 - 100 years of manufacturing

A highlight of our business is hitting the road and visiting our manufacturers. Unfortunately we were only able to squeeze in one trip this year - 5 states in 4 days and over 800 miles driven in a rental car! We visited a brand new mill that just opened in 2019 and our fabric finishers that have been in business since 1919! We visited the world’s most advanced yarn spinning mill that has over 1,000,000 square feet under one roof! (That’s 21 acres of building and one of the largest textile mills in the country.) It’s all about people and understanding how important these businesses are to their local communities. They’re often the largest employer in town and a backbone of that city, supporting hundreds of jobs and families. And these skilled factory jobs are essential to our country; People working together to make things happen, face to face, mixing hands and machinery.

We hoped that the monumental disruptions we saw in 2020 would go away in 2021 - but they’ve actually gotten worse. We’re seeing inflation across all of our products; the cost of Supima® cotton has doubled, and shipping and freight expenses have increased dramatically. Even as our business has grown, manufacturing costs on all of our products have gone up, not down. Nearly all of our manufacturers are having trouble finding workers, and we’re experiencing unprecedented delays - that we’ve never seen or experienced before.

Global crisis - domestic repercussions

For example, getting yarn for our sheeting fabric has been a nightmare. (The Uighur humanitarian crisis in China caused a large portion of the global long-staple cotton crop to be black-listed by many companies, causing a run on American-grown Supima® cotton. That situation combined with our yarn spinner’s labor challenges created large obstacles for us to get yarn as production has slowed when it should be ramping up.)

However, these challenges aren’t unique to us - they’re happening across all industries and sectors. It’s important to understand that what has kept us in business is our relationship with our manufacturers, and the trust and respect we’ve developed with them. The fact that we’ve spent many months on the road in the past to visit them, tour their facilities and get to know them and their families, on a real, authentic level. We love working with our great partners across the country and they understand our vision for A50 - they know that we will never ever offshore our production overseas and that we are fully committed to being long-term partners.

Price Increases in 2021

Unfortunately, due to the challenges described above, on top of the increases in freight, shipping and storage costs we’re going to have to increase prices on some of our products. We’ve been absorbing these costs for over a year - hoping things would return to normal as we move past Covid - but rather than improve they’ve only gotten worse. Since we opened our doors in 2016, we’ve had just one price increase - on our sheet sets. We don’t want to raise prices, but we’ve realized that we need to do so, in order to sustain the business. If you compare our premium 100% Seed-to-Stitch® Made in USA home goods to that of any overseas made competitor (that uses low-wage labor in unregulated factories) you’ll see that our products are actually very competitive in price.

In particular, bulky items will see price increases as they’re directly impacted by rising costs. Freight, shipping, storage and raw materials, unfortunately, have been on a one way course lately and these are all more sensitive to size and weight. All this to say that NOW is the time to buy anything you want or need from our site, especially as the holidays creep up on us. Better to buy now while we’ve got your item in stock, than wait until November when inventory is uncertain and prices go up!

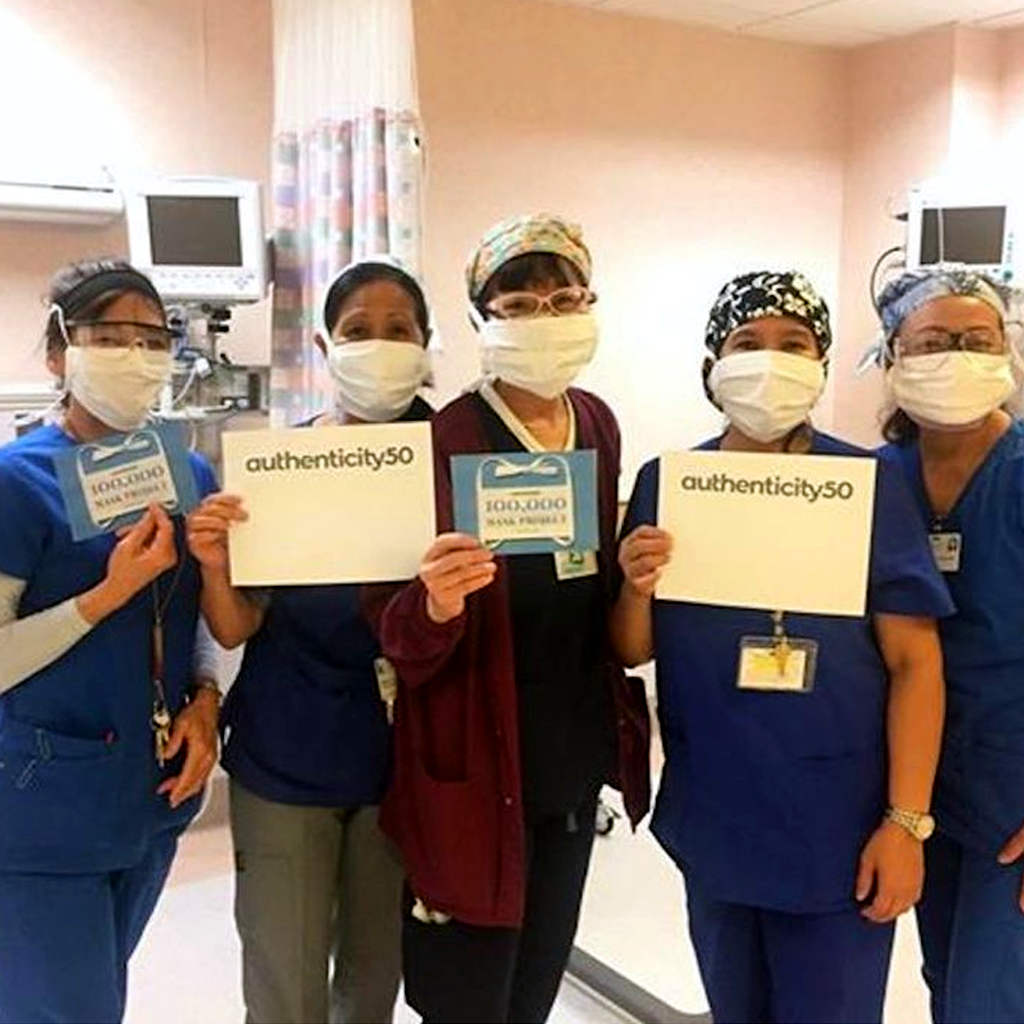

Covid-19 & the 100,000 Mask Project

For those of you who don’t know, we (Jimmy and Steph) lived in Japan and China for several years and have many friends in both countries. In early-February before it caught on in the domestic press we were hearing about Covid from our friends overseas and debated cancelling a trip to Hawaii to introduce our new baby to Steph’s 99 year old Grandma. We decided, albeit with some trepidation - to continue on with our short trip before things got too bad. What a difference a few weeks makes - by the time we were headed home the news was starting to talk about the spread of Covid in the US, the first cases were confirmed in Washington state and travel via air was quickly falling out of favor.

We knew that masks would be in demand and health care workers across the country were suffering from a shortage of PPE - so we decided to jump in and help. Our connections and expertise in domestic manufacturing allowed us to link up with different manufacturers in order to turn our sheeting fabric into high quality masks. We donated enough fabric to make 100,000 masks but wanted to do more. The costs to make a mask here in the USA are significantly higher than overseas, however, it’s not a large amount of money compared to the importance of the product.

We discovered that we could cut and sew a mask for $1.30 and set off with the goal to pay for the sewing of 100,000 masks. It was an audacious goal and thanks to you, we raised enough to create and distribute over 20,000 masks across the country! While we didn’t reach our ambitious goal, we did what was right and are incredibly grateful for YOUR contributions - we owe it all to you and are so very thankful for your support! It shows that this country is at it’s best when times are at their worst - that even with all the uncertainty, you were willing to step up and put your money where your mouth is for a good cause. It inspired us and keeps us going!

We successfully donated masks to:

- Johns Hopkins All Children's Hospital, Orlando FL

- Loma Linda University Medical Center, CA

- University of Maryland Medical Center, MD

- Atrium Health Hospitals, SC, NC, GA

- Orlando Health Regional Medical Centers, FL

- Kuakini Health System, HI

- Covid Action Coalition Team, MA

3,000 miles traveled or 23,000 miles traveled. Less Greenhouse Gases = Better for the Environment

As parents, we constantly think about the environment and our place as stewards of the planet for the next generation. We want our children to grow up healthy and live on a planet that’s abundant with life, clean air and water. We want Authenticity50 to be a power for positive change, and probably the most powerful, empowering and positive thing you can do for the planet, as a consumer, is to buy local. Products made locally don’t have the massive carbon footprint from dirty cargo ships that are shipping raw materials and finished goods tens of thousands of miles around the globe. Most people don’t know this, but the cargo shipping industry creates more pollution than all the cars on the planet. And it’s been estimated that just one super cargo ship, as long as 6 football fields, creates more pollution than 50 million cars. Currently 100's of cargo ships are sitting off-shore near our domestic ports waiting to be unloaded, and causing more pollution to our coastal waters.

When you buy local, you support local communities and jobs but you also support a much LOWER carbon footprint. Authenticity50 has one of the lowest carbon footprints of any bedding and home goods company. Our sheets start with cotton grown in California, it’s then sent by rail to Georgia where the yarn is spun, and the entire production process from there takes place in a radius of less than 1,000 miles. Compare that to sheets made from American-grown cotton, which is then shipped to India or China for weaving (to take advantage of cheap labor and lax environmental regulations) only to be shipped all the way back to the USA as a final product. Sheets can travel more than 20,000 miles before they reach your door! Or they can travel less than 1/10th of that when made locally.

We’re actively exploring how we can make A50 better stewards of the environment. Whether it’s examining eco-friendly packaging materials or simply making longer lasting products - we are on this journey and we take it seriously.

A50 Renewed by RND2

To reduce our carbon footprint, and offer you great value, we’re launching an innovative partnership with Tersus Solutions and their re-commerce brand RND2. They’re well known for their renewal collaboration with Patagonia and other large apparel retailers, and we’re excited that they wanted to work with our smaller home goods brand. They’ll be taking our gently used returns, sanitizing them with their high-tech liquid CO2 cleaning machine, then repairing as necessary and reselling the certified products on their site. Most of these products are in excellent condition with only one or two washes when the customer felt the product wasn’t right for them. Or maybe they have a stitch that failed but is easily fixable. RND2 allows us to close the gap on textile circularity and create sustainability - we’re able to keep our products out of landfills, put them back into consumer use, and provide our customers with an affordable option to get A50 products - renewed items are 40 - 50% off depending on condition! Better for the environment, better business and better for you - win win win! The launch happens soon, so watch your inbox for the announcement!

Growth

Despite the challenges of 2020, the business grew by nearly 50%. We actually had a difficult time keeping products in stock, as people re-examined the values of the companies that they purchased from and re-examined their living spaces. Signature Sheets, Duvet Covers, Custom Comfort Pillows, and Essential Cotton Towels all went through multiple rounds of being sold out during the year and trying to get them back in stock was more challenging than ever due to freight and logistics headaches.

With the growth, we’ve brought more people on to our team - we’ve expanded our Customer Happiness team and work with more manufacturers and contractors to help us achieve our goals.

What you can do - word of mouth

Word of mouth continues to be the most important way for us to market our business and we appreciate you spreading the word to all of your family, friends, neighbors and frenemies! Our goal is to spend minimally on advertising and instead invest heavily in making great products. Most companies operate like this: $100 selling price = $70 on marketing to acquire a customer, $15 to make the product and $15 profit. We want to operate like this: $100 selling price = $50 to make the product, $15 on marketing to acquire a customer and $35 profit. This allows us to invest in a BETTER product, pay our manufacturers fairly and make a fair profit so that we can continue to operate and sustain the business.

Your word of mouth helps us keep the model above, make a superior product and pay all of the people we work with fairly. Outsourcing to India and China isn’t done because they make a better product - it’s because the manufacturing costs are so low it allows them to spend $2 million on a Super Bowl ad.

Better Products

We continually strive to make the best home goods on the market today. We always take your feedback into account to see how we can improve our products, and we’re constantly examining our entire product range to see how we can make things better. We work hard to launch great products in the first place - so the changes are often small things here and there that add up over time to make a product better than it was 2-3 years ago. An example of this is our Custom Comfort Pillow ticking fabric - we’d like to improve the cooling and breathability of the fabric without sacrificing durability. We’ve made one round of improvements and are working on round 2 as we speak. You probably wouldn’t be able to tell the difference from one version to the next, but we’d know and we want to offer the best.

Another example is the elastic in our fitted sheets. Since we started we’ve always used a tucked elastic in the fitted sheet (meaning that the fabric covered the elastic so it wasn’t visible) but last year we experimented with a thick, heavy duty 1” external elastic. There were numerous benefits to this thicker elastic but you all let us know you preferred the old way - so we’re going back to the tucked elastic. Sometimes the best way to get the best product is to let the customer tell you what they like. :)

New Products

In Summer 2020 we launched our Heritage Blankets via a pre-order campaign that we thought would sell a couple hundred units. Instead, it took off, quickly growing to over 1,000 units! Our manufacturers in Maine were of course thrilled by the size of our orders, but also experienced challenges as they tried to juggle manufacturing during a pandemic. They did a great job of getting us blankets as fast as they could and we thank you all for sticking with us through those delays. Our premium blankets are popular, and we’ll continue to add new colorways and additional weaves in the coming year ahead.

We’re also developing several other products that we had to shelve in 2020 due to Covid. We’re about 75% there on bathrobes (a project we started in 2019), and we hope to bring them to market in 2022. So please stay tuned! We get many requests for masks from you all as well and while we’ve made over 20,000 of them - they’ve been very utilitarian in design and focused on the healthcare industry. We’ll keep you posted if we dive deeper into masks and let us know if that’s something you’d like.

In Closing

We’d like to reiterate how much we appreciate your support - whether you’re a current customer, future customer or simply a fellow Made in USA fan! It means so much to us that you have read this far, and that you want to know what’s going on with A50. Thank you for being on this journey with us, we’re grateful for you. And please reach out to us and our team with any thoughts, feedback and ideas - we always love hearing from you!

Wishing you all a safe and healthy season ahead,

Jimmy, Steph and Team A50

9 comments

Jessica

This was very interesting! Thank you for taking the time to share. I had never heard of RND2 — just checked out their website (and bookmarked it for a future jacket purchase). What a great idea! Despite the fact that I actually worked in the container shipping industry some years ago, I still find it difficult to wrap my brain around the amount of goods that are moved across the planet every day. It’s unbelievable and, obviously, unsustainable. So far we have four of your heritage blankets in our house, in all available colors, and I look forward to seeing future variations of those. The small ones are perfect on the couch and the big ones – wow! – they really are the most wonderful compliment to our wool & cotton California-made mattresses (we are fully aware that we are truly spoiled). :) Thank you for making it possible for us to have these beautiful Made in USA blankets in our home. I hope things improve (for everyone, everywhere!) very soon.

Jiles36

Jimmy when are you gonna do flannel sheets?

Barbara Awarski

I just purchased a Heritage blanket. Very pleased with product. I am always looking for MADE IN USA. Wishing you the best.

Liz Jones

Thanks for the update. Enjoy reading about your suppliers, as a spinner (as in fiber) I really appreciate knowing where things come from. The cotton bale photo was amazing. We were early adapters with your sheets and most recently purchased your wool duvet. Having slept under down duvets most of my life, what a joy it is to snuggle under wool. It is the “Goldilocks” of duvets not too heavy, not too light, not too warm, not too cold.

Corey

Thank you so much for posting this! Glad to hear that you are chugging along despite challenges. Also thank you for keeping focus on the importance on your supply chain and labor. I consider A50 to be among a handful of incredibly important manufacturers here. You’re in good company with American Giant and Schiit Audio.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.